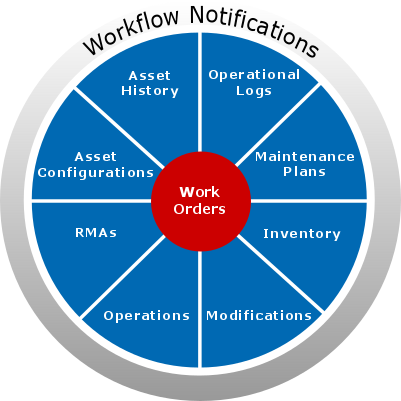

MaintenanceMaintenance work orders interact with most of the major functional areas of COLTS:

Learn more about maintenance... |

|

Work Orders

Work Order Details

- Open work order by quickly looking up or scanning barcode of item under repair

- Request and receive parts from inventory

- Document maintenance actions using the customizable actions library

- Perform quality assurance to ensure integrity of repair operations

- Automatically capture Repair Time, Turnaround Time, Logistic Delay Time, Q/A Delay Time, Adminstrative Delay Time, and personnel hours

- Create a parent/child work order tree for component repairs

Asset Configurations

- Modify asset configurations directly from work orders

- Capture configuration change history automatically

- Scan equipment on/off configurations using UIDs

Asset History

- Troubleshooting, failures, calibrations, repairs, quality assurance, and more

- Configuration changes

- Inventory usage and consumption

- Equipment status changes

- Failure trend analysis

Return Mechandise Authorizations (RMAs)

- Request and approve RMAs directly from original corrective work order

- Replacement automatically shipped upon approval

- Link between original corrective work order and return work order

Inventory

- Direct link between maintenance and inventory

- Supply personnel can see material requests, check availability and issue parts

- Authorized techs can requisition material, issue parts directly to work order

Operational Log

- Record operational metrics on item under repair and components

Maintenance Plans

Planned Maintenance

- Condition-based maintenance

- Calendar-based maintenance

- Automatic scheduling of maintenance work orders

- Maintenance task library includes task time and material requirements

Corrective Maintenance

- Design corrective maintenance plans including tasks and material requirements

- Link work orders to corrective plans to automatically populate task, time, and material requirements

Modifications

Modification Management

- Identify and describe each modification

- Select assets requiring modification

- See modification time/date completion for each asset

- Track completion progress for modification

- Modification requirement alert when work order opened

- See modification details

- Record modification completion

Return Mechandise Authorizations (RMAs)

- RMA request and approval cycle

- Replacement item shipped automatically upon RMA approval

- Returned item work order

- Comprehensive RMA status of original request, return, replacement, and repair

- Track return and replacement shipments

- Estimated and actual repair cost approval cycles